WIND TUNNEL

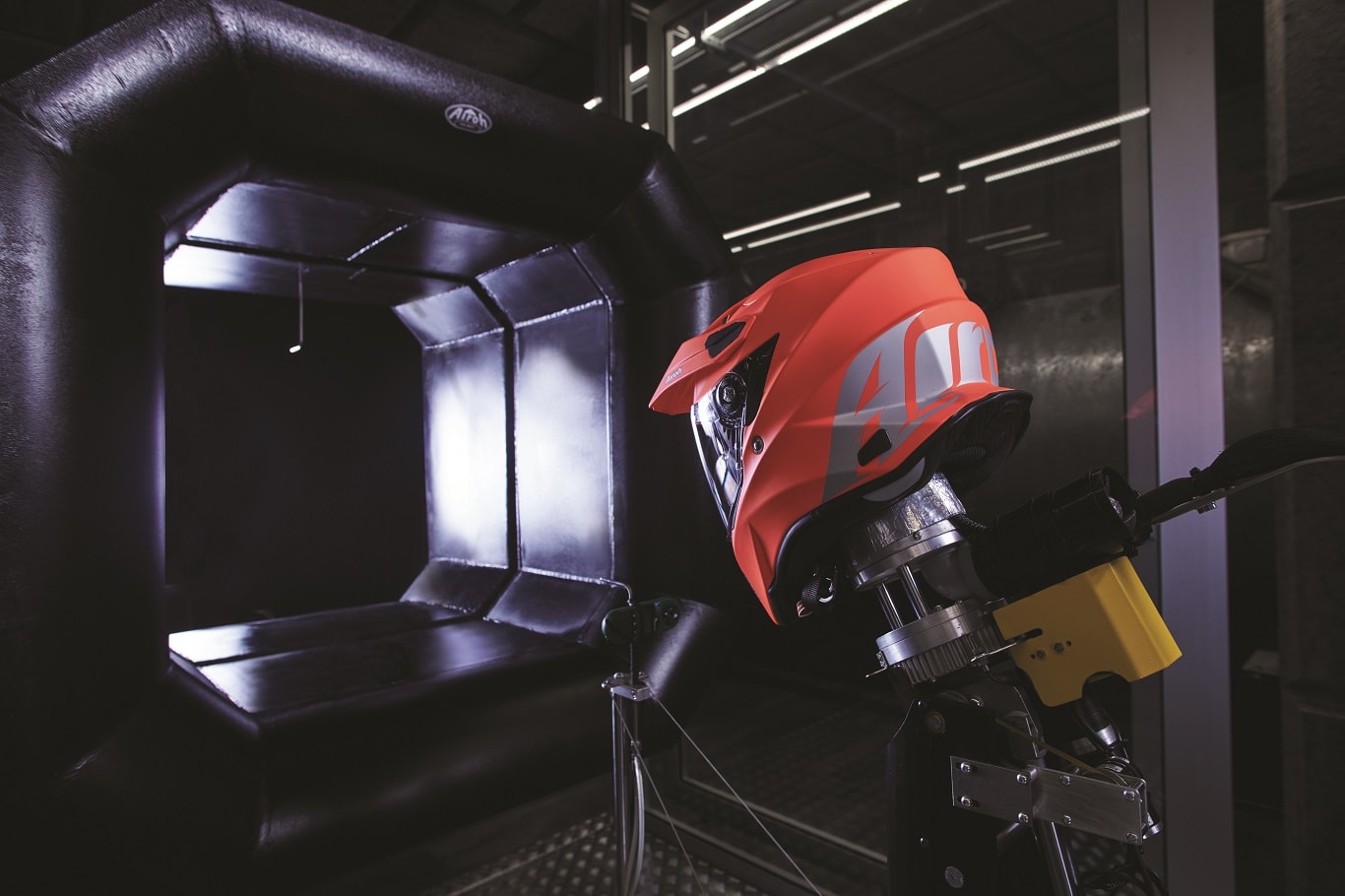

A constant drive, an endless flow. The wind, an immaterial, though real element, drives and supports dreams and concepts, to make projects and products excellent. Airoh is fully aware of the direction to take and for this reason got its own wind tunnel, which very few companies in the motorsport panorama can boast. Harnessing the wind and making it run along the road conceived by an incredible design. This allows the helmet’s aerodynamic, acoustic and thermal performance to be checked thoroughly. Research, technology, innovation and passion naturally meet to be used in a sophisticated system made to improve performance. The strategy that ignites our company is always the same, that is to say searching for continuous improvement. To get the best, we contacted the best. A pool of engineers, in synergy with our Research and Development department, worked for more than six months to create a revolutionary wind tunnel. Powered by subsonic, closed-cycle Gottingen technology, and designed to be used both in open and closed test chambers according to the specific programs; the software, exclusively owned by Airoh, was developed on advanced algorithms able to take unique measurements. Specifically, the lateral movement and inclination of the dummy head is predicted through a remote-controlled computer, allowing for the analyses of the results by testing any type of scenario on and off road. The power harnessed in our wind tunnel simulates the most extreme conditions of use; with more than 200 km/h reached, it is possible to test the aerodynamic, acoustic and thermal levels in the helmet. The number of tests that can be performed is stunning; ranging from aerodynamic, static or in movement tests to displaying the flows, the side strength, acoustic and thermal measurements at different speed, all constantly monitored and subsequently processed with the most advanced computerised and 3D display analysis systems. Specifically, the tests also rely on the pressure sensors and two microphones assembled on the dummy head. The instruments actually analyse the noise caused by the air flow on the helmet’s surface and any possible turbulence generated. Measuring is divided into determination of the sound level (dBA), octave analysis and frequency. Special attention is paid to analysing the stagnation points, the separation lines and the transition boundary between the laminar and the turbulent layer; in this sense, special tracers are used at the solid and gas state, which are able to highlight the aerodynamic strength result. Thermodynamics is especially important for those helmets that are worn for several hours, with challenging temperatures, in very different scenarios. It is for this reason that the dummy head is able to constantly monitor the temperature on its surface; in this sense a 3D image is obtained where the different temperatures of the test are highlighted with various colours. Usually, in the first phase of the test, the head reaches an ideal temperature for benchmarking and appears red; while performing the test, areas subject to different temperatures are highlighted in different colours. This change is generated by the effectiveness of the air vents and the air extractors, which perform a fundamental role in ensuring optimal comfort. Meticulous attention to details, relentless and untiring search for the best performance and the desire to have motorcyclists wear the same product as the most successful champions, have pushed Airoh to obtain a truly unique wind tunnel. Only in this way can a helmet be given the AWT2 (Airoh Wind Tunnel Tested) title.